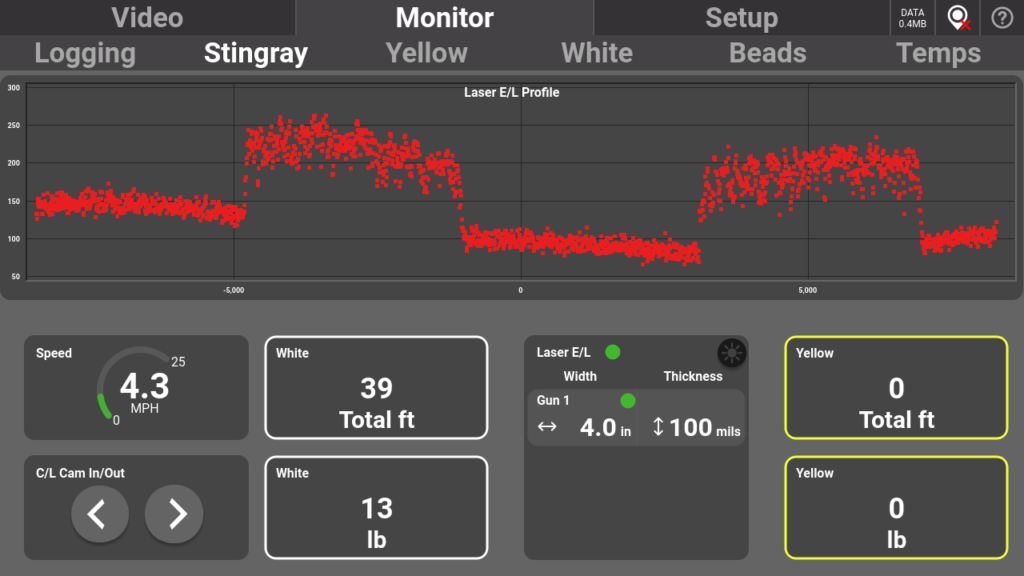

Say goodbye to wasted material, inaccurate applications, and unnecessary risks. STINGRAY™ is the most advanced thermoplastic paint monitoring system available today, providing real-time data to ensure your road markings are precise, compliant, and cost-effective. Whether you’re outfitting new paint trucks or retrofitting an existing fleet, STINGRAY™ delivers the accuracy, efficiency, and safety your team needs.

Traditional monitoring methods are unreliable, leading to inconsistent applications and wasted materials. STINGRAY™ eliminates the guesswork by using laser-accurate sensors that provide real-time feedback, ensuring your road markings meet specifications every time.

How accurate is STINGRAY™?

Stingray™ uses laser technology to measure line thickness and width in real time, ensuring 100% accuracy without manual intervention.

How much can I save with STINGRAY™?

By eliminating over-application, users save up to $5,000 per truck per day in material costs. Most users recoup their investment in under 90 days.

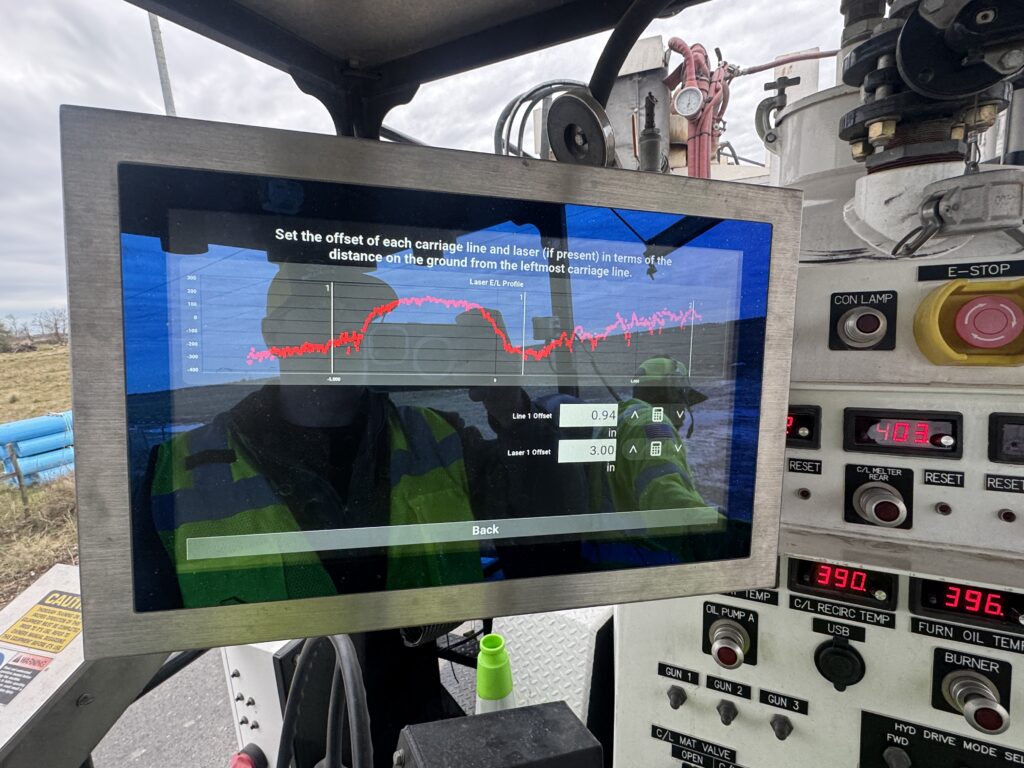

Is STINGRAY™ difficult to install?

Not at all. It installs on most trucks in less than a day and requires no major modifications.

Is it compatible with all trucks?

Yes. Stingray™ can be retrofitted onto any truck, seamlessly integrating with Skip-Line systems.

How does it improve safety?

By eliminating manual checks, operators can stay inside the truck, reducing road exposure and risk.

Does STINGRAY™ work in all weather conditions?

Yes. Stingray™ is built for durability and functions reliably in any climate.

Do operators need extra training?

No. STINGRAY™ is intuitive and integrates seamlessly with Skip-Line systems, requiring no additional training.

Experience Stingray™ in action. Contact us today for a live demo and see how it can transform your road marking operations.

The Best Striping Technology