When it comes to road striping, there’s no room for guesswork—especially with reflective bead application. DOT compliance standards are non-negotiable, and the stakes are high: visibility, safety, and your reputation are on the line.

But until now, crews haven’t had access to real-time, per-gun bead flow data. ACCU-BEAD™ changes that—giving your team the visibility they need to get it right the first time.

The Compliance Challenge: Meeting Spec with Confidence

If you’ve ever had to re-stripe a job because of failed retroreflectivity readings, you know how frustrating (and costly) it can be. The testing process itself isn’t the issue. It’s the lack of visibility during application that puts crews at a disadvantage. Without a clear way to track bead flow in real time, ensuring spec compliance becomes a guessing game. And when the results come back days or even weeks later, the damage is already done.

Failing a retroreflectivity test doesn’t just mean wasted material. It means lost time, rework, and if it happens more than once—reputational damage that could cost you future bids.

Getting It Close Isn’t Close Enough

Even the most experienced crews can only do so much without real data. Visual checks are common in the field, but they don’t capture the subtle variances in bead flow that can lead to noncompliance. Slight inconsistencies between guns, from shifting conditions, or even equipment wear can go unnoticed in the moment. It might look right, but if the coverage isn’t precise, that line could fail inspection days later.

Underapplied beads result in low retroreflectivity, making lines harder to see at night—a serious safety concern. And overapplication, while often unintentional, can cause beads to scatter, distort the color of markings, or simply waste expensive material.

The ACCU-BEAD™ Advantage: Real-Time Precision, Built for the Jobsite

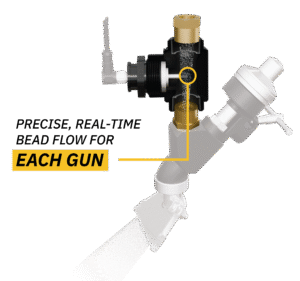

ACCU-BEAD™ is the industry’s first system to provide real-time, per-gun bead flow monitoring—offering a level of control and insight crews have never had before.

Its patented in-flow design delivers accurate, live data without being affected by truck movement, vibration, or heat. That means dependable measurements, even in the real-world conditions your crews face every day.

Key benefits include:

- Real-time flow rates for each individual gun

- Rugged, IP67-rated construction for durability in harsh environments

- Seamless integration with Skip-Line’s DL-18 data logger and Spec-Rite Online for advanced reporting and compliance tracking

- Metrics including pounds of beads per gallon, per mile, and per square foot

Why It Matters: Avoid Rework. Protect Your Reputation. Deliver Safer Roads.

With ACCU-BEAD™, your crew gets the data they need—when and where it matters. Instead of relying on estimates or after-the-fact corrections, you can fine-tune application in the moment, ensuring every job meets spec the first time.

And when inspections come, you’ll be ready—with confidence in your application rates and a digital audit trail to back it up.

Learn more about how ACCU-BEAD™ helps you stay compliant, reduce liability, and build safer, more reliable roads.