Pouring money down the drain is one thing, but how about pouring time down the drain? In road striping, every minute a truck is off the road costs you. When you’re dealing with retroreflectivity specs, failing to meet them doesn’t just impact safety; it means frustrating, costly rework that eats into your schedule and your profit.

It’s time to stop letting antiquated bead monitoring methods sideline your operations.

The Bottlenecks of Outdated Bead Management

Traditional approaches to monitoring reflective bead application are often a major source of unnecessary downtime. Think about it:

- Manual Checks & Guesswork: Relying on visual inspections or “gut feelings” means you’re operating blind. By the time you realize there’s an issue, your crew has already wasted valuable time and material.

- Tank Scale Systems: While they offer some data, these systems are notorious for their installation headaches. We’re talking about days of truck downtime, needing cranes, heavy lifting, and complex recalibrations. That’s not just inconvenient; it’s a full-blown operational disruption.

- Rework: The biggest time sink of all. When lines fail inspection due to incorrect bead application, your crews are pulled off new projects to go back and fix old ones – on your dime. This isn’t just about lost material; it’s about lost momentum and damaged reputation.

Your crews are highly skilled, but without the right tools, they’re constantly battling inefficiencies that grind your operations to a halt.

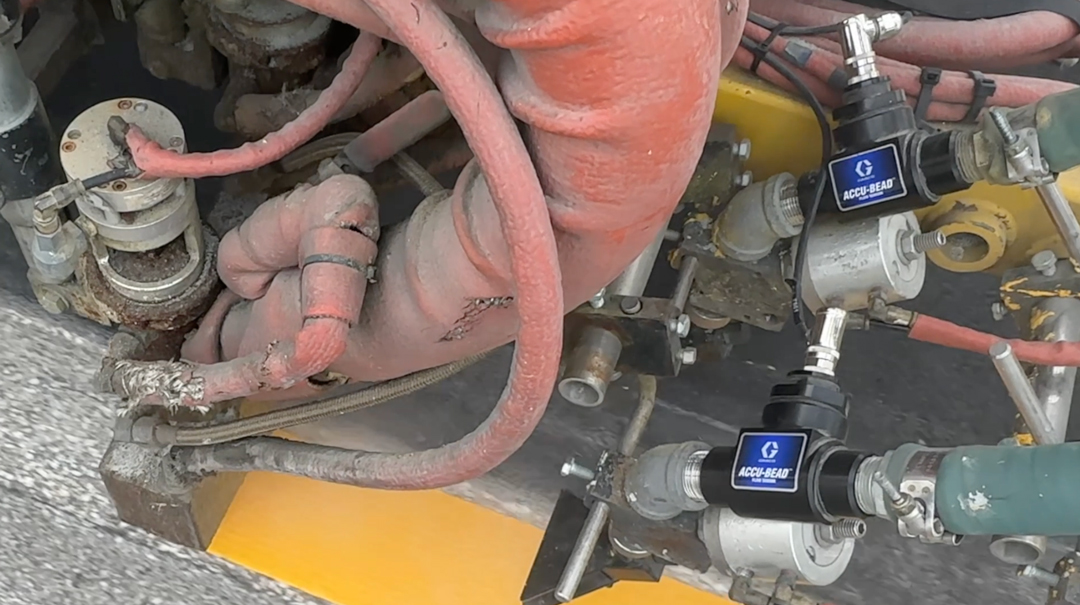

ACCU-BEAD™: Designed for Speed, Built for the Road

What if you could eliminate those headaches and keep your trucks productive? ACCU-BEAD™ is engineered precisely for that. We designed it with one goal in mind: to give you pinpoint accuracy with minimal disruption.

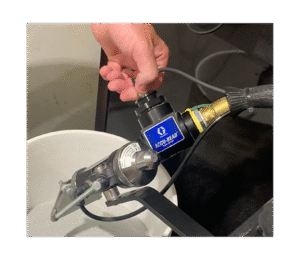

Forget about lengthy installations and complex setups. ACCU-BEAD™ installs with basic hand tools, without truck modifications or heavy equipment. This means:

- Faster Deployment: Get up and running in a fraction of the time compared to scale-based systems.

- Maximum Uptime: Your striping rigs stay where they belong – on the road, completing jobs and earning revenue.

- Instant Precision: Once installed, ACCU-BEAD™ provides real-time, per-gun monitoring of bead flow. This means your operators can make adjustments on the fly, preventing over- or under-application before it becomes a problem. No second passes, no expensive do-overs.

ACCU-BEAD™ works seamlessly with virtually any existing bead gun system and is compatible with all types of reflective beads. It also integrates perfectly with Skip-Line’s DL-18 data logging system and Spec-Rite Online, giving you comprehensive visibility from the field straight to your office.

See How Quickly ACCU-BEAD™ Powers Up Your Operations

We get it – seeing is believing. You want to know that a solution can genuinely minimize your downtime and improve efficiency without adding complexity.

See exactly how ACCU-BEAD™ installs and operates, and why contractors trust it to keep their crews moving and their jobs on track.

Don’t let unnecessary downtime dictate your schedule or chip away at your profits. Equip your team with the precision and speed they need.

How many truckloads of beads have you wasted?