You wouldn’t pour money down the drain—but if your crews are running bead guns without real-time monitoring, you might be doing exactly that.

Reflective beads are a critical part of every striping job, ensuring safety and compliance, but overuse is common and costly without visibility into how much you’re applying.

Most contractors don’t realize it’s happening until it’s too late—thousands of dollars in material waste per project, quietly chipping away at profit margins. Whether you’re a private contractor or a DOT crew, unchecked bead flow can be a hidden drain on your bottom line.

Beads don’t lie. And once you have the data, the numbers tell a powerful story.

The Problem: Waste You Can’t See

Even highly experienced striping crews can’t manually track bead flow with the precision required to avoid waste. What looks correct to the eye can easily be off by 10%, 20%, or more—leading to measurable financial loss and unnecessary risk.

Here’s where the damage shows up:

Material Waste: Reflective beads are one of the most expensive consumables in a striping project. Over-applying by even a small margin on every mile of road adds up fast—and those excess costs are hidden unless you have visibility.

Profit Erosion: Every extra pound of beads eats into your margin, making it harder to stay competitive and maintain profitability, especially when bids are tight.

Hidden Rework: Misapplied beads can result in failed inspections, callbacks, and additional crew time on site. These hidden costs not only delay project timelines but also erode customer trust.

One DOT contractor we spoke to was stunned to discover they were overapplying by nearly 25%—a hidden inefficiency they only uncovered after installing a bead flow monitoring system. That revelation changed the way they bid and execute jobs going forward.

Why “Eyeballing It” Doesn’t Work

Striping is precision work—but when it comes to bead flow, even the most skilled operators are often left guessing. The reality is, too many variables are at play for manual observation to be enough:

- Inconsistent Flow Rates: Factors like humidity, equipment wear, bead size, and hopper condition can cause flow rates to shift unexpectedly.

- Multiple Guns, Multiple Variations: On rigs with several bead guns, keeping all nozzles flowing evenly is a constant challenge—without real-time monitoring, it’s impossible to spot small discrepancies.

- Feedback Comes Too Late: By the time the job is inspected or finished, the opportunity to adjust has passed—and the wasted material is already on the ground.

In the end, relying on experience alone can cost you more than you realize. Without data, even the best crews are flying blind.

The ACCU-BEAD™ Solution: Real-Time Data on Every Job

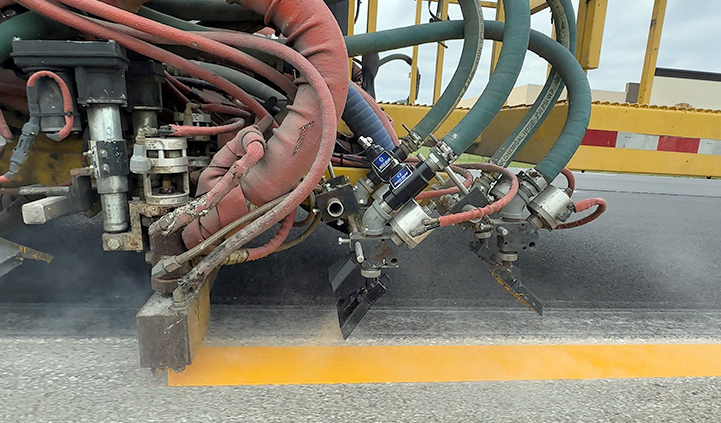

ACCU-BEAD™ is a precision-engineered flow sensor designed to retrofit easily onto any existing bead gun system. Instead of leaving bead flow to chance, it provides real-time, per-gun monitoring—turning what was once invisible into actionable data your crews can trust.

provides real-time, per-gun monitoring—turning what was once invisible into actionable data your crews can trust.

Key benefits include:

- Cut Bead Waste by Up to 30%: Live flow data allows your crew to adjust in real time, ensuring you only apply what’s needed—no more, no less.

- Protect Profit Margins: By eliminating unnecessary material waste, you stop bleeding money on every project.

- Simplify Compliance: With accurate flow monitoring, you can meet DOT and client specs with confidence—reducing the risk of failed inspections or costly rework.

Beads don’t lie—and neither does ACCU-BEAD™. It gives your team eyes on every bead, every time.

Numbers Matter. Do you Know Yours?

The only way to protect your margins—and your reputation—is to measure what matters. ACCU-BEAD™ provides the visibility and control your crew needs to:

- Stop guessing

- Start saving

- Stay compliant with every job

Don’t wait to find out the hard way how much you’ve been losing.