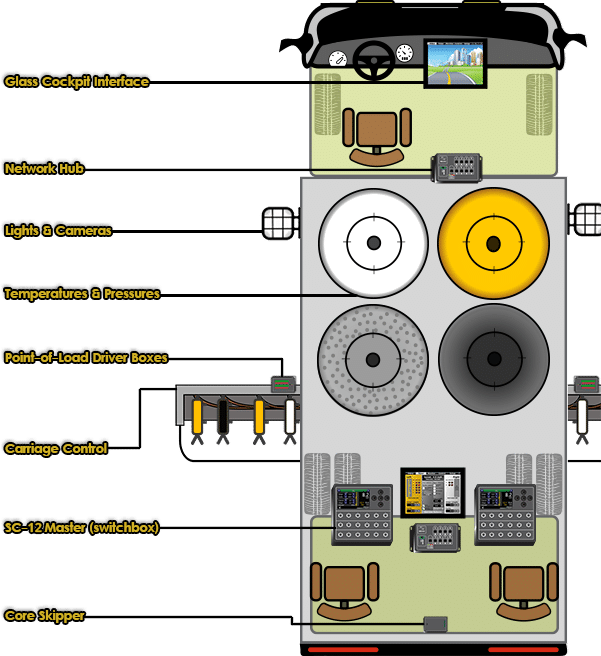

The SC-12 Control System is the most advanced skip timer on the market. The SC-12 provides advanced striping and truck control capabilities by creating a single, integrated electronic system for nearly the entire striping truck. Operators can control hydraulic and pneumatic pressures, temperature control, application rates, lights, cameras, linear actuators, and more. The system has powerful diagnostic features that enhance operators’ in-the-field awareness and troubleshooting capability.

Optionally integrate nearly any peripheral truck function to create a single, networked electronic system for the entire striping truck.

Using one integrated system means that the entire crew can learn all aspects of the operation. The SC-12 provides an intuitive interface, reducing the need for specialized training.

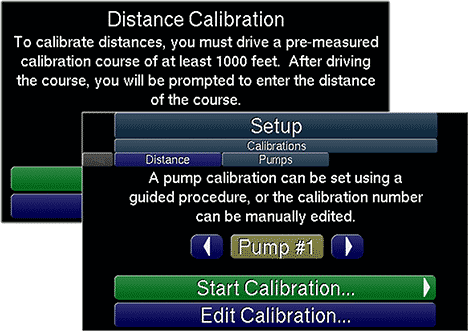

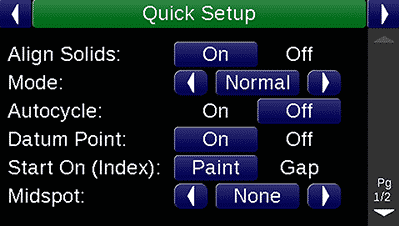

Straightforward menus and shared configuration between devices makes setup easier than ever before. A large LCD display clearly conveys system messages and parameters.

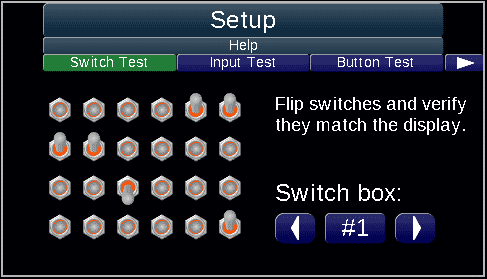

Built-in diagnostic and troubleshooting features minimize vehicle down time and maximize productivity. Every output device has a status indicator which makes isolating an issue easy.

Promote Safer operations with a Skip-Line™ Glass Cockpit near the vehicle driver. Monitor real-time application rates and simplify pattern configuration with a Glass Cockpit near the rear operator stations.

Provide clean communications and LED diagnostics. Conveniently place hubs near SC-12 Control System devices to reduce wiring.

Move and focus cameras, turn work lights on and off, and engage linear actuators.

Control material temperatures and hydraulic/pneumatic pressures.

These can be mounted in a sealed enclosure on or near the carriage to reduce wiring or in the console in the operators area. Output indicators help with installation and diagnostics. LED lights indicate activated channels.

Take command of the carriage with gun raisers and advanced carriage movement capability.

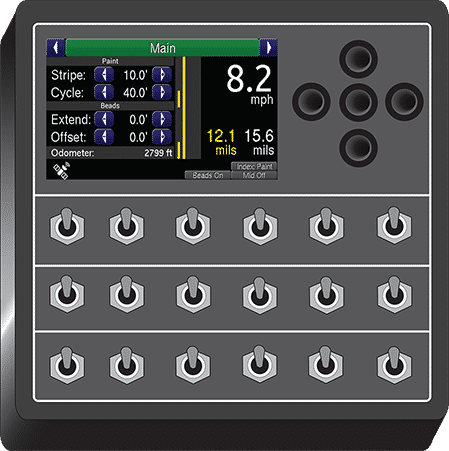

An SC-12 Master provides operation stations with system control. Engage road marking with rugged toggle switches. Change pattern configuration and more using a simple navigation menu.

The Core Skipper calculates and implements the striping pattern as dictated by the operator. It ensures the most accurate striping at any speed. Usually mounted in the console in the operator’s area. Speed and pump sensors are connected here.

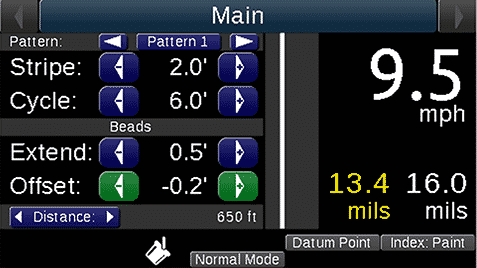

VIEW THE MOST RELEVANT STRIPING INFORMATION WITH A GLANCE

View a pattern before it’s applied for a confident, error-free setup.

Monitor material application rates right on the main screen.

View important messages and system statuses without entering submenus.

The main screen displays key operating information in a manner that is quickly understood with a brief look so operators can focus more on the striping operation.

In addition to instant or average application rates, the main screen clearly displays vehicle speed, active striping features, and an invaluable pattern preview. Adjust cycle settings and bead registration from the main screen as well.

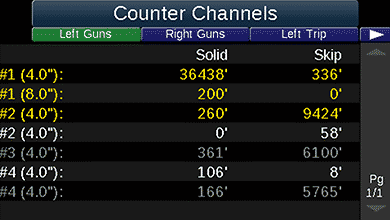

Track simple metrics such as distances and paint usage with built-in counter channels. Upgrade to Advanced Counter Channels for metrics by pattern for jobs that pay by pattern distances.

Provides the same functionality as our legacy skip-timer product lines but includes these distinct advantages:

Switch and menu features that come standard with a base SC-12 Control System. Menu features are very intuitive and quickly accessible with the new full-color display. Navigate the menu with rugged, sealed push buttons.

The base system includes the following devices:

A third master swtichbox that can override either of the rear operator stations to take control of a carriage. While not overriding another switchbox, the Cab Master displays animated pattern previews from both carriages.

Control gun raisers using additional SC-12 Master switches. Eliminate relays with H-Bridge output boxes.

Additional driver outputs for lights, valves, pumps, and more. Engage outputs with the SC-12 Master, a satellite switch box, or external toggle.

Toggle switch control box for custom control functions.

Handheld rework trigger for manual or semi-automatic skips. Connect to any BUS-012 Hub port.

Industrial thermal paper tape printer for printing job counter channels and material usage.

Remote speedometer/counter, commonly called “speedo” for driver use

Special switch and menu features that can be added to a base SC-12 System. Many additional features and patterns are available.

The Best Striping Technology